Overview

Construction drawing media selection directly impacts the clarity, durability, and professional presentation of architectural plans. The right combination of paper type, weight, and plotter settings determines whether your technical drawings withstand job site conditions while maintaining precise detail reproduction.

TL;DR

- Bond paper (24 lb minimum) provides the best balance for most construction drawings

- Vellum offers superior durability for field use but costs 40% more

- Plotter settings should match the media type for optimal ink absorption

- Mylar film excels for archival drawings requiring 50+ year preservation

- Coated papers deliver sharper lines but take longer to dry

Introduction: Why Construction Drawing Media Matters

Here's the thing: choosing the wrong media for your construction drawings can lead to smudged details, torn corners on job sites, and costly reprints. Construction drawing media isn't just paper - it's the foundation that determines how well your technical specifications communicate in the field.

Professional construction firms process hundreds of drawing sets monthly, and media selection affects both print quality and project costs. Whether you're printing detailed architectural plans or quick reference sheets for field crews, understanding media options helps you balance quality with budget.

Understanding Construction Drawing Paper Types

Bond Paper: The Workhorse Standard

What most people don't realize is that bond paper effectively handles 80% of construction drawing needs. At 24 lb weight (90 gsm), standard bond paper provides adequate durability for office review and limited field use. The uncoated surface accepts both inkjet and toner well, making it versatile across different plotter types.

Bond paper works best for:

- Daily working drawings

- Internal review copies

- Short-term project documentation

- Budget-conscious high-volume printing

Vellum: Built for the Job Site

So how does vellum compare to standard bond? Vellum's translucent, tear-resistant properties make it ideal for overlaying drawings and surviving harsh construction environments. The material costs approximately 40% more than bond paper but lasts significantly longer in field conditions.

Vellum characteristics include:

- Enhanced tear resistance (3x stronger than bond)

- Moisture resistance for outdoor use

- Excellent pencil and ink receptivity

- Overlay capability for comparison work

Mylar Film: Archival Excellence

When drawings require decades of preservation, Mylar polyester film delivers unmatched durability. Architecture firms typically reserve Mylar for final as-built drawings and legal documentation. (Yes, it's expensive, but sometimes necessary.)

Selecting the Right Weight and Thickness

Paper weight significantly impacts construction drawing media performance. Industry standards recommend:

20 lb Bond (75 gsm): Acceptable for draft prints and internal reviews only. This weight tears easily and shows ink bleed-through on complex drawings.

24 lb Bond (90 gsm): The construction industry standard, balancing cost and durability. Handles normal handling without tearing, minimal show-through.

28 lb Bond (105 gsm): Premium option for presentation drawings and client-facing documents. This product provides a professional feel and enhanced durability.

32 lb Bond (120 gsm): Specialty weight for drawings requiring frequent handling or outdoor exposure. This material resists tearing and moisture better than lighter weights.

Here's what determines optimal weight selection: drawing complexity, handling frequency, and environmental exposure all factor into the decision.

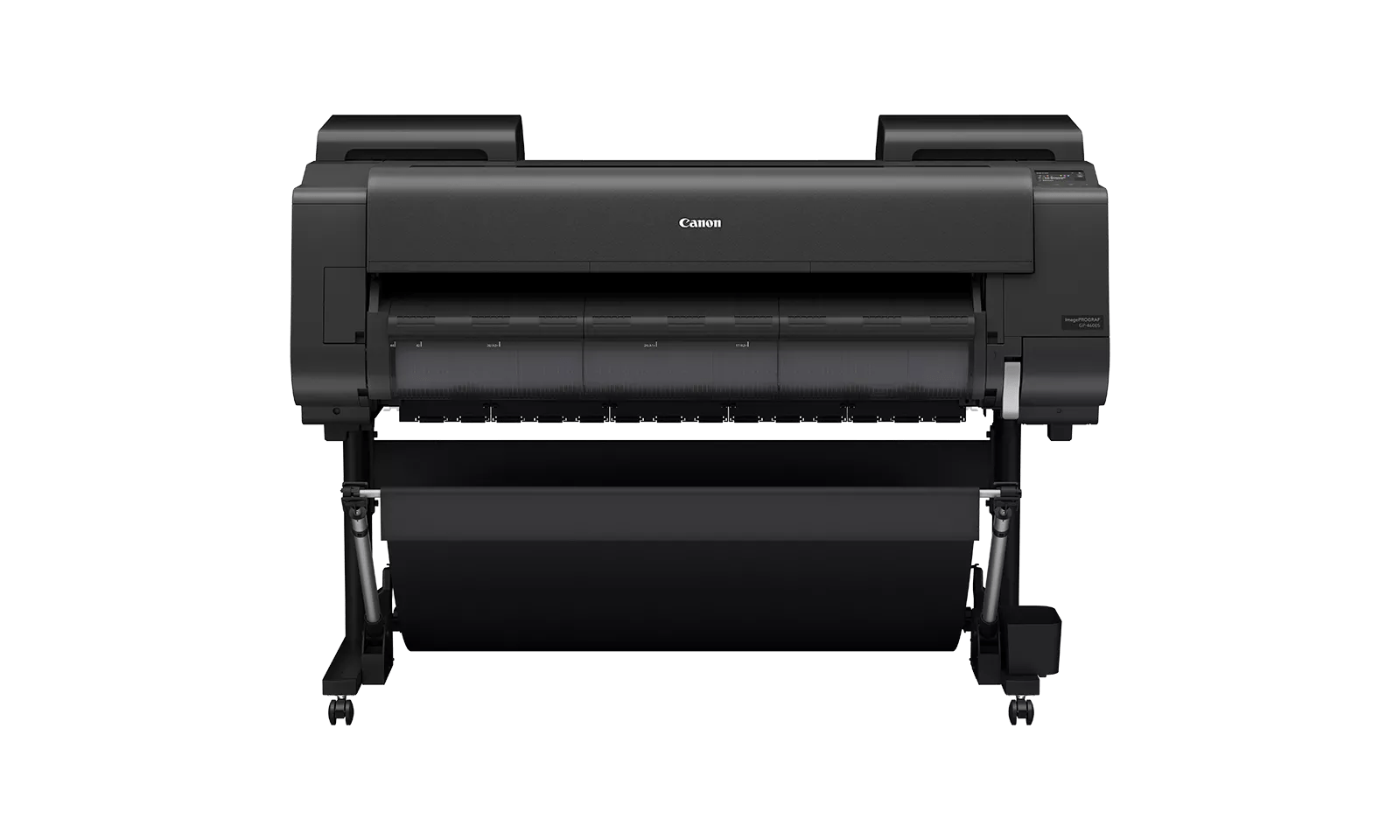

Optimizing Plotter Settings for Different Media

Matching Settings to Media Type

Your plotter's media settings directly affect print quality and ink consumption. Canon TM Series plotters, for instance, offer preset profiles for various construction drawing media types. Adjusting these settings prevents ink bleeding on absorbent papers and ensures proper adhesion on coated surfaces.

Key setting adjustments include:

- Ink density (reduce 10-15% for vellum)

- Drying time (increase for coated papers)

- Print speed (slower for heavyweight media)

- Color saturation (adjust based on paper absorption)

Troubleshooting Common Media Issues

What about those frustrating print quality issues? Most problems stem from mismatched media settings rather than printer malfunction. Streaking typically indicates excessive ink for the selected media, while fading suggests insufficient ink density or incorrect paper type selection.

Cost Considerations and Budget Planning

Construction drawing media costs vary significantly based on volume and quality requirements. Let me explain the typical pricing structure:

Budget planning should factor in:

- Monthly print volume estimates

- Ratio of draft to final prints

- Field versus office use percentages

- Storage requirements for bulk purchases

Key Takeaways

- Match media weight to usage: 24 lb bond for standard drawings, 28 lb for presentations

- Vellum justifies higher cost for field drawings requiring durability

- Proper plotter settings prevent 90% of print quality issues

- Bulk purchasing reduces per-sheet costs by 15-20%

- Consider archival needs when selecting between bond and Mylar

Frequently Asked Questions

Q: What's the best construction drawing media for outdoor job sites?

A: Vellum or synthetic papers provide optimal outdoor performance. Vellum offers natural tear resistance and moisture tolerance, while synthetic options like Tyvek deliver waterproof properties. For temporary outdoor use, 28 lb bond with water-resistant coating works adequately at lower cost.

Q: How long can I store unused plotter paper before quality degrades?

A: Properly stored plotter paper maintains quality for 2-3 years. Store rolls vertically in climate-controlled environments (60-75°F, 35-55% humidity) away from direct sunlight. Sealed packages extend shelf life, but opened rolls should be used within 6 months for optimal performance.

Q: Should I use matte or glossy paper for construction drawings?

A: Matte paper works best for construction drawings requiring annotations and field markups. The non-reflective surface reduces eye strain and accepts pencil marks readily. Glossy papers suit presentation drawings where color vibrancy matters, but they're impractical for working documents due to glare and marking difficulty.

Q: What causes my construction drawings to curl after printing?

A: Curling results from a moisture imbalance between the paper sides after printing. Heavy ink coverage on one side causes that side to expand. Solutions include using heavier-weight paper (28 lb minimum), allowing proper drying time, and storing prints flat under weight for 24 hours post-printing.

Ready to upgrade your construction drawing media selection?

Contact our technical specialists for personalized recommendations based on your specific plotter model and project requirements. We offer sample packs to test different media types before committing to bulk purchases.

About the author:

Kevin Vaughan is the President of TAVCO. With over two and a half decades of experience, he has received various awards for sales performance and channel growth. Published articles focus on AI-powered AEC technologies, CAD software, and large-format technology. When he is not geeking out on new technologies, you can find him hanging with his wife and kids, playing guitar, or Scuba diving.

1 comment

Zoe Campos

Thank you for featuring the different types of paper that can be used for wide-format printers. My mother recently told me that she needs bond paper for her work. I should find bond paper rolls for her near our area soon. https://getpaper.com/itasca